Situation: Stock Administration for Retail

You’re the Knowledge Science Supervisor of a world clothes group that has shops all all over the world.

The distribution workforce is managing the replenishment of shops from native warehouses.

Your colleague, the Stock Supervisor, is accountable for setting the shop replenishment guidelines within the ERP.

She has applied a periodic evaluation coverage Order-Up-To-Degree (R, S)

- The ERP is reviewing shops’ stock ranges (additionally known as stock readily available) each R days: IOH

- For every evaluation, the hole between the stock stage and the goal stock S is calculated: S — IOH

- A Replenishment Order is created and transmitted to the warehouse with the amount Q = S — IOH

The concept is to ship the lacking amount to achieve this goal stage.

After transmission, the order is ready on the warehouse and delivered to your retailer after a sure lead time LD (days).

The goal inventory is outlined to soak up the demand variability and the replenishment lead time to keep away from stock-outs (empty cabinets) on the retailer.

I cannot enter the main points of tips on how to set these variations on this article.

Nevertheless, should you want extra data, you’ll find an in depth clarification on this article.

Among the many key parameters of this rule is the time between two opinions, which is able to drive the frequency of replenishment in your shops.

What if we modify this evaluation interval?

What’s Inexperienced Stock Administration?

The evaluation interval is setting the frequency of retailer replenishment order creation.

- For R = 2 days: shops are replenished very steadily

You possibly can set a decrease goal inventory stage to cowl the demand through the evaluation interval. - For R = 15 days: shops are replenished much less steadily

The order amount per replenishment have to be greater as your goal inventory stage wants to soak up the demand throughout a longer evaluation interval.

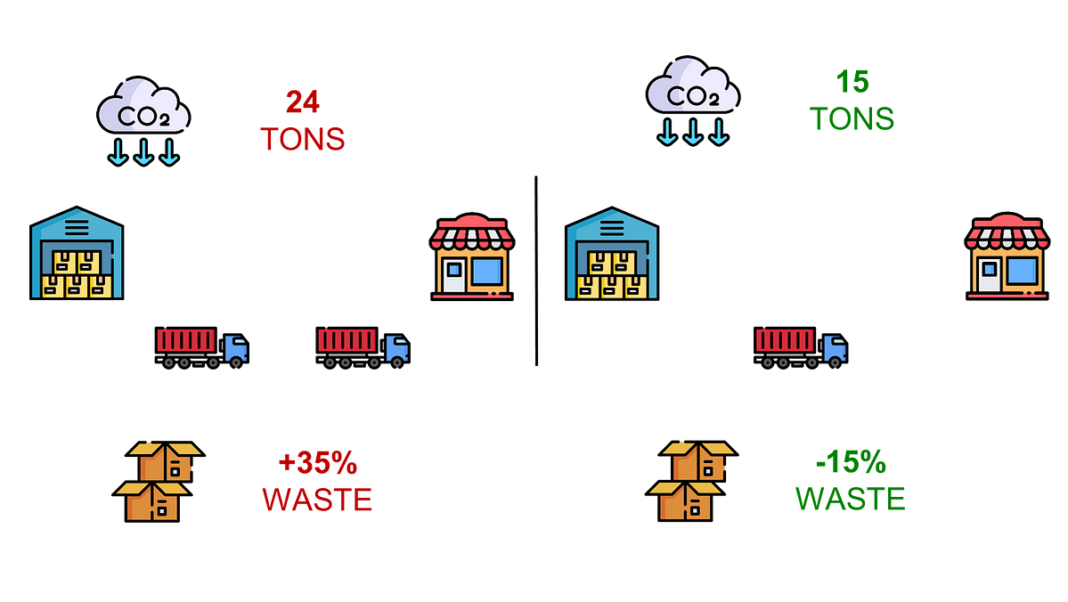

On the left facet, we’ve got extra retailer deliveries (with a decrease amount per cargo) for a similar length.

This may positively affect the effectivity of your warehouse and transportation operations.

Can we estimate the impacts of those two totally different approaches on the CO2 emissions?

You possibly can simulate these and assist your colleague estimate the affect of her stock guidelines on the consumption of cartons and CO2 emissions.

Impression on the carton utilization

Gadgets are delivered on the shops in cartons containing items picked individually.

If the shop orders 5 items of the reference XXX, the operator will

- Open a field of 20 items and take 5 items;

- Take a brand new field and put these 5 items;

- Full the field with different objects ordered by the shop;

We should use further carton materials to create these blended cartons containing totally different objects. (as a substitute of transport full cartons)

What number of further blended cartons do we’ve got to arrange?

You possibly can calculate the whole variety of blended cartons utilizing the system beneath.

These bins (or blended cartons) would require further packing materials that may affect your footprint.

With the next replenishment frequency, the amount per replenishment is decreased, and this example can happen extra.

Can we estimate the affect on the Transportation effectivity?

Impression on transportation emissions

As it’s the principal driver of CO2 emissions, you also needs to estimate the affect on the variety of vans used and their filling price.

The evaluation interval impacts the variety of deliveries throughout a sure interval.

As an example, doubling the supply frequency will

- Multiply the variety of delivers for the same amount replenished;

- Scale back the amount per replenishment and doubtlessly enhance the house in vans

How can we translate these insights in estimated CO2 emissions enhance?

Within the subsequent part, we are going to translate these operational insights right into a simulation mannequin to pick out the optimum stock guidelines.